The Benefits of Investing in High-Quality Industrial Scales for Heavy Weighing

The Benefits of Investing in High-Quality Industrial Scales for Heavy Weighing

Blog Article

Everything About Industrial Scales: Trick Functions and Advantages for Your Work Environment

Industrial scales are essential in improving functional effectiveness throughout different fields, offering functions such as high ability, precision accuracy, and robust building. Recognizing the diverse kinds and applications of commercial ranges can provide beneficial insights into maximizing your workplace processes-- yet, the trip does not end there.

Types of Industrial Scales

Industrial scales are critical tools used across numerous sectors for exact weight measurement. One common type is the system range, which offers a big evaluating surface area ideal for cumbersome and heavy products.

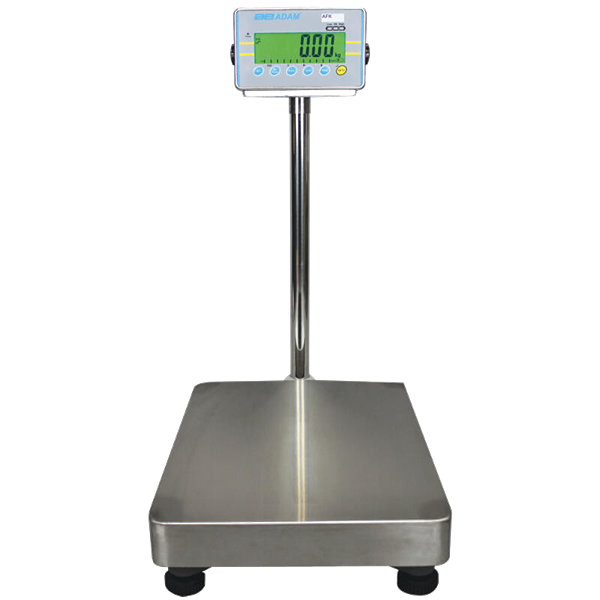

Another widespread type is the bench range, which is compact and ideal for smaller things. These scales are regularly discovered in retail and food solution settings, where quick and exact measurements are needed. Floor scales offer a comparable purpose yet are developed for durable applications, allowing for the considering of huge pallets and containers directly on the ground.

Furthermore, digital scales have actually obtained appeal as a result of their convenience of usage and precision. They typically include sophisticated electronic devices that enhance performance, such as connectivity choices for data tracking. In addition, portable scales offer adaptability for on-the-go evaluating, making them invaluable in areas like agriculture and logistics.

Understanding the various kinds of industrial ranges is crucial for selecting the right devices to fulfill specific operational demands, making sure performance and accuracy in weight measurement.

Key Attributes of Industrial Scales

When choosing the ideal type of industrial range, it is essential to consider the vital features that boost their functionality and viability for specific applications. Among one of the most vital features is the scale's capacity. Industrial scales are readily available in different weight abilities, ensuring that they can suit the demands of various sectors, from light materials to heavy tons.

Another important feature is precision. High-precision load cells are essential for making sure that dimensions are consistent and reliable, which is essential for inventory management and top quality control. Furthermore, the readability of the screen plays a significant function; clear, digital screens with flexible illumination enable very easy viewing in different lights problems.

Resilience is an additional crucial characteristic, with many industrial scales developed to stand up to harsh settings, including exposure to dampness, chemicals, and hefty usage. Some designs also include waterproof or stainless-steel building and construction. Additionally, connection alternatives such as Bluetooth or USB enable seamless data transfer and assimilation with other systems.

Benefits for Ergonomics

Furthermore, industrial scales make it possible for faster processing times. With automated considering remedies, employees can swiftly get weight data without manual estimations, liberating time for various other essential tasks. This velocity in process not just improves functional performance yet also helps satisfy manufacturing deadlines better.

Furthermore, commercial scales offer valuable data that can be evaluated for constant enhancement. By keeping an eye on weight patterns, organizations can recognize inadequacies in their procedures and execute rehabilitative activities, inevitably resulting in boosted efficiency.

The assimilation of these scales likewise sustains compliance with industry policies, as exact coverage of weights is frequently required. This lowers the threat of costly penalties and improves the firm's credibility for dependability. Industrial Scales. Overall, the unification of industrial scales adds to a more efficient, cost-effective, and compliant office environment

Applications in Various Industries

In the food industry, commercial ranges are used for portion control, dish formula, and conformity with health laws, guaranteeing food security and consistency. In a similar way, in the pharmaceutical sector, accurate considering is vital for medicine formulation, where also small inconsistencies can lead to significant regulative concerns and security concerns.

Building and construction and logistics sectors additionally gain from industrial scales, as they aid in enhancing and managing raw materials delivery procedures. By providing exact weight information, these ranges promote far better tons preparation and compliance with transport guidelines.

In addition, the agricultural field employs commercial ranges for weighing animals, feed, and produce, thus boosting functional efficiency and making certain reasonable trade techniques.

Upkeep and Calibration Tips

To guarantee optimum efficiency and durability of industrial ranges, regular upkeep and calibration are crucial. A constant upkeep schedule helps recognize possible concerns prior to they rise, therefore lessening downtime and fixing expenses. Operators must regularly cleanse the range to avoid particles buildup, which can influence accuracy (Industrial Scales). In addition, evaluating the load cells, circuitry, and screen for wear or damages is click here to read important.

Calibration is similarly important; it makes sure that the range provides exact analyses based on sector requirements. It is suggested to calibrate scales regularly-- at the very least annually or even more regularly if the scale is utilized greatly or relocated regularly. Follow the maker's guidelines for calibration procedures, which typically include utilizing qualified calibration weights.

Additionally, keeping correct environmental conditions, such as temperature and moisture control, can improve scale efficiency and accuracy. Educating personnel on correct use techniques will even more guard versus misuse that might lead to errors or damages. By sticking to these upkeep and calibration tips, services can guarantee their industrial ranges run successfully, inevitably sustaining productivity and compliance with regulatory requirements.

Conclusion

In recap, industrial scales offer as important instruments for boosting work environment performance throughout varied fields. By understanding the essential functions and advantages of commercial scales, organizations can utilize these devices to enhance product use, minimize waste, and ultimately drive performance.

Industrial scales are pivotal in improving operational effectiveness across different markets, offering functions such as high capability, precision accuracy, and durable building and construction.When choosing the suitable type of commercial scale, it is important to think about the crucial features that improve their functionality and suitability for specific applications. By giving precise weight dimensions, commercial ranges remove the potential for human error, making sure that products are weighed continually and precisely. It is suggested to calibrate scales frequently-- at the very least once a year linked here or more frequently if the scale is utilized greatly or moved frequently. By understanding the key features and advantages of commercial scales, companies can leverage these tools to improve product application, lower waste, and inevitably drive performance.

Report this page